Metal may seem like a solid, stable material — one that you can rely on to hold its shape and remain true to itself under stress. In reality, it is subject to all kinds of movement when subjected to heat. These thermal stresses need to be countered to maintain the integrity of the object.

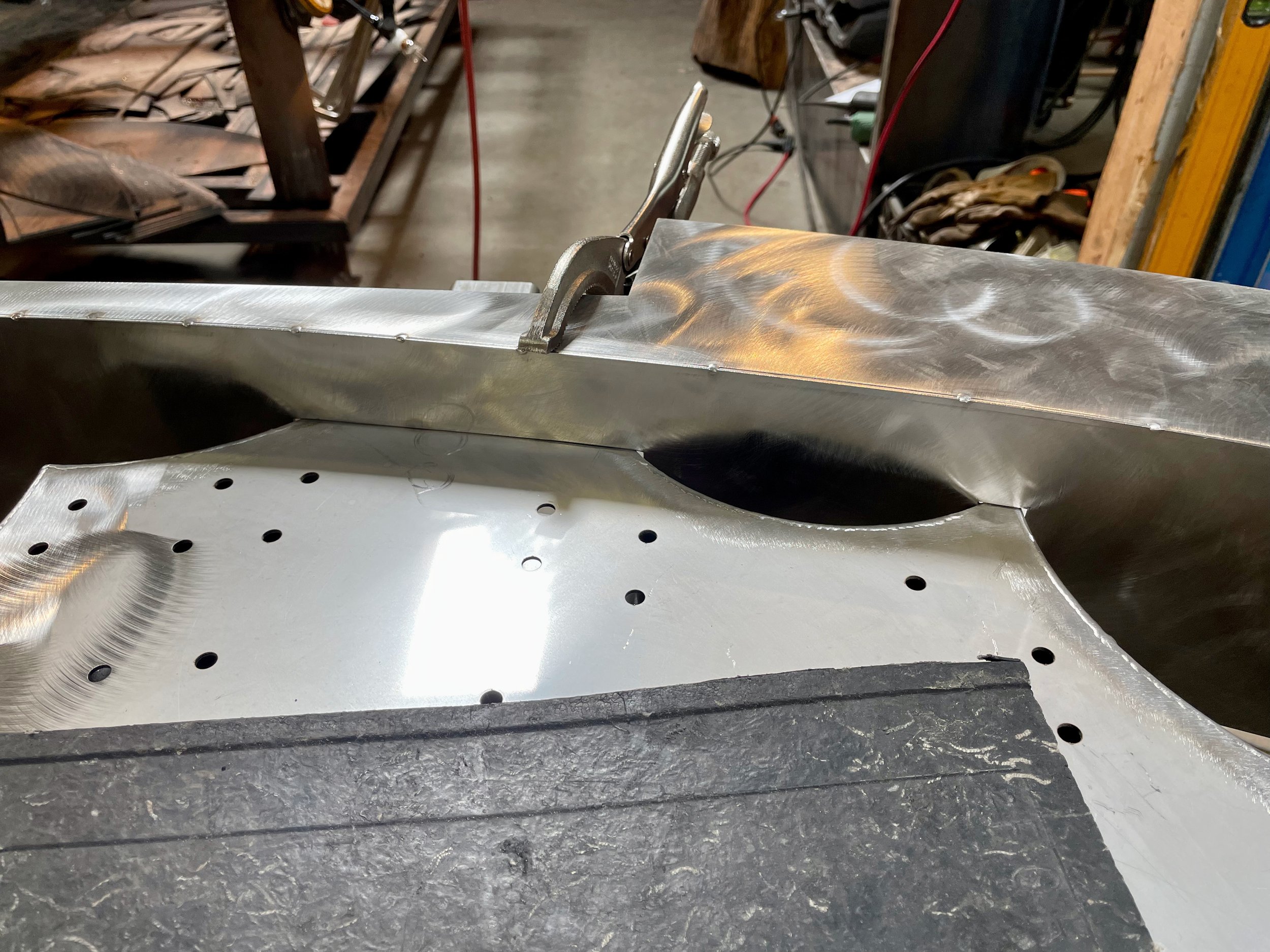

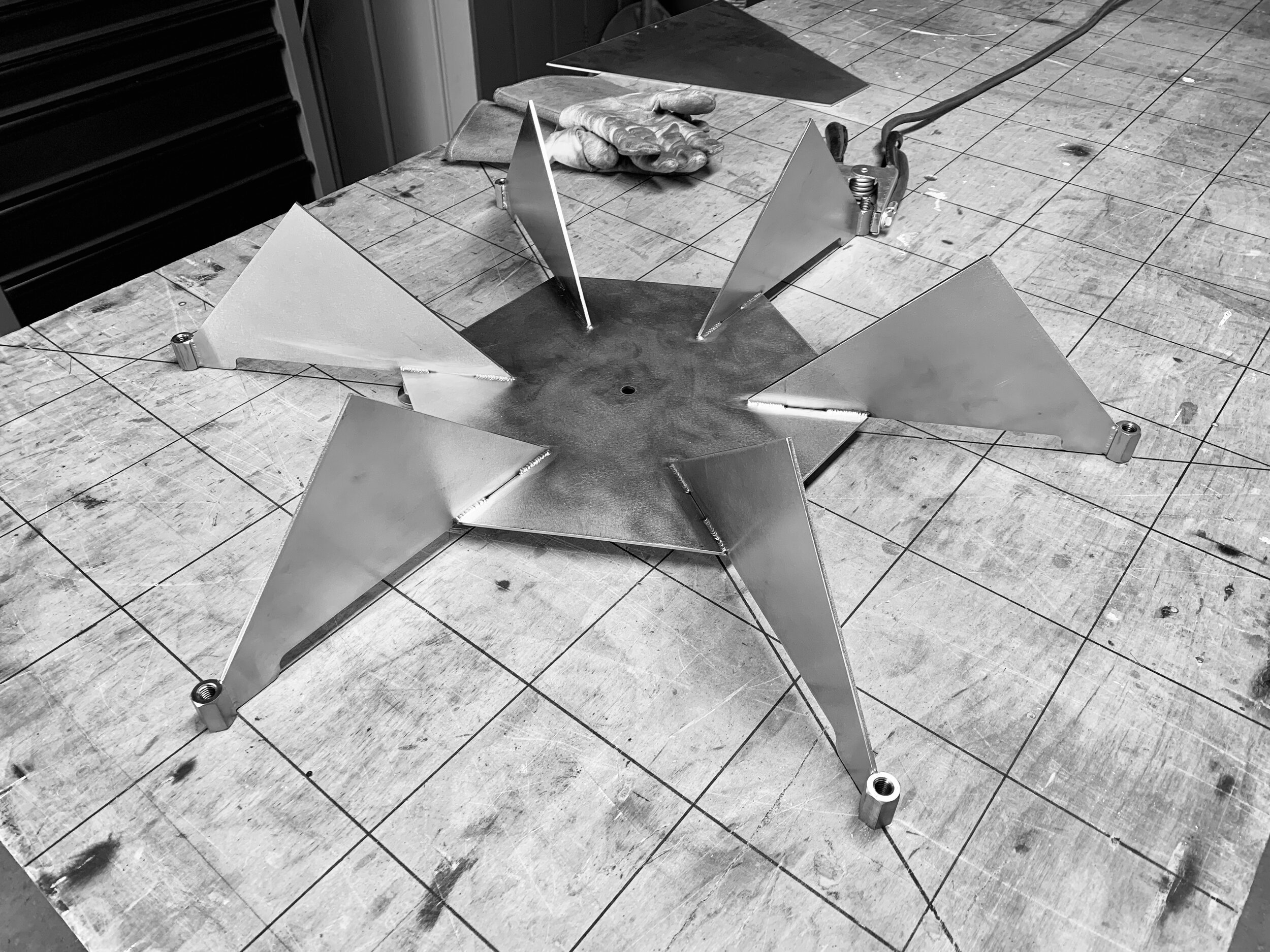

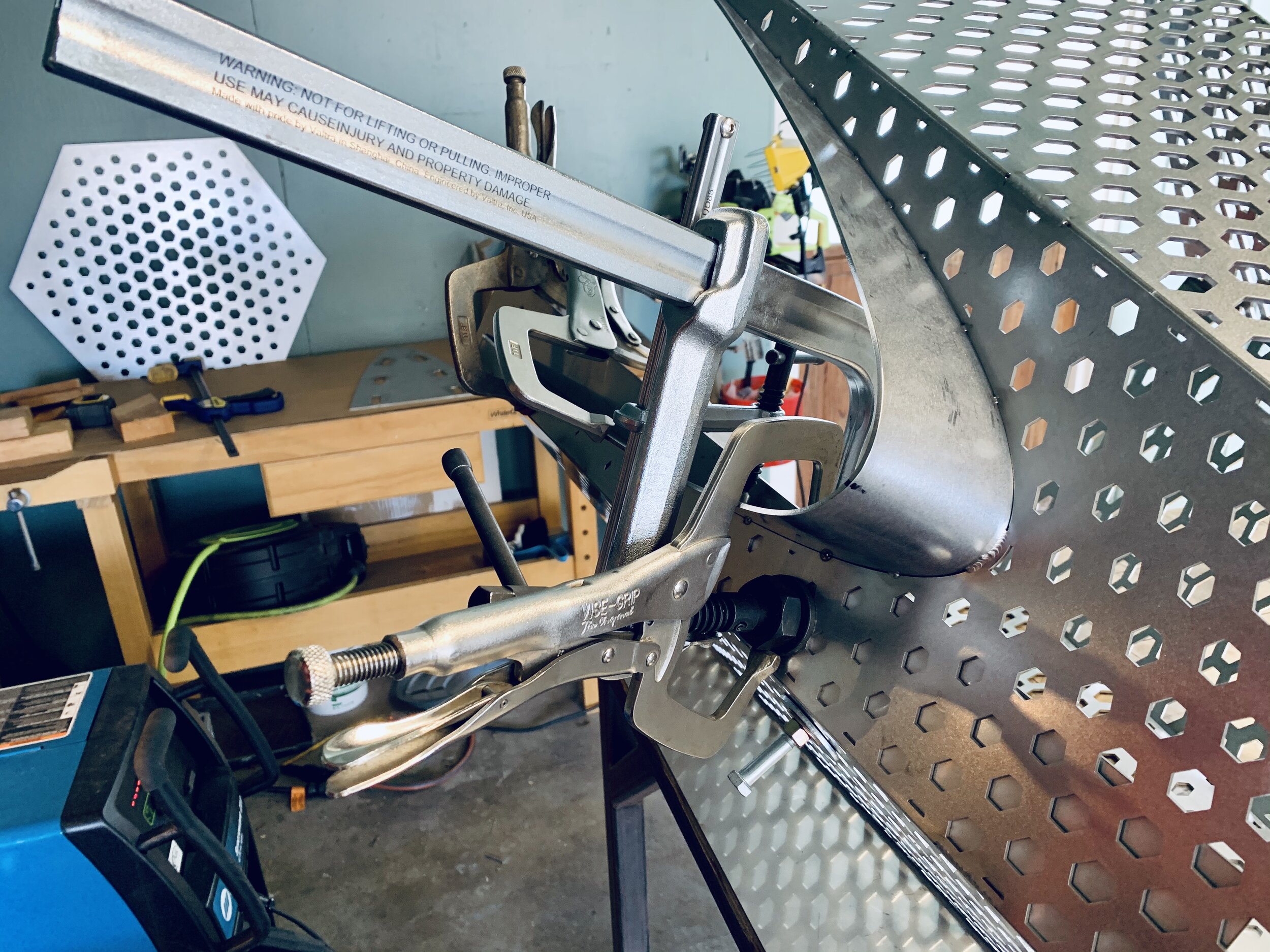

The aftermath of our stress test showed that the outer “shell” of the design handled these forces well — but the grill itself, directly in contact with the source of heat, needed some shoring up. Any welder can tell you that one only need curtail expansion and contraction throughout the heating cycle to minimize warping. The grill was allowed too much freedom in this design, and the forces went to work on it. I needed to do some redesigning, but thought I’d try to retrofit the V1.0 CinderCone before tackling V2.0.